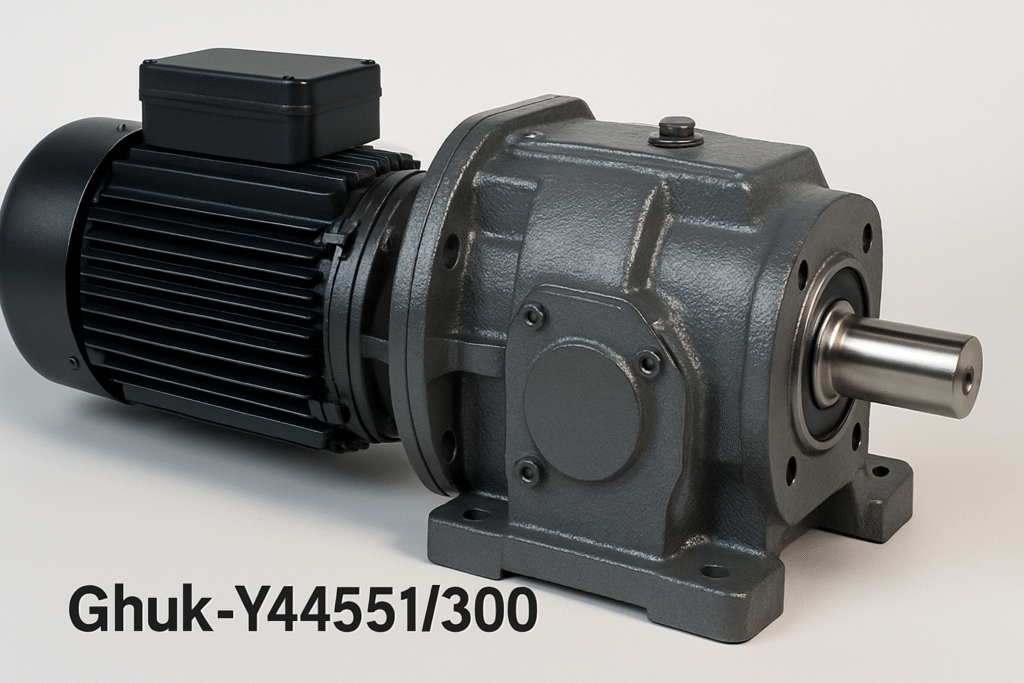

The Ghuk-Y44551/300 is a high-performance industrial gear motor widely recognized for its precision, durability, and efficiency in demanding mechanical systems. Designed with advanced engineering, this unit is often used in sectors where consistent torque and reliability are non-negotiable. Whether applied in conveyor systems, automated machinery, or heavy-duty equipment, the Ghuk-Y44551/300 delivers exceptional power transmission and energy efficiency.

Built for maximum uptime, it balances power with low maintenance, making it a top-tier choice for engineers and procurement officers across industries. In this article, we’ll explore everything from specifications and applications to advantages and maintenance practices of the Ghuk-Y44551/300.

Technical Specifications of Ghuk-Y44551/300

Understanding the technical side of this gear motor helps determine its suitability for your project. The Ghuk-Y44551/300 typically features:

-

Power Rating: Varies from 0.75 kW to 7.5 kW depending on the model

-

Gear Ratio: Precision ratios between 5:1 and 300:1

-

Torque Output: High torque range up to 800 Nm

-

Voltage Compatibility: 230V/400V

-

Mounting Options: Foot or flange-mounted

-

Enclosure: IP65-rated dust and water protection

-

Lubrication: Factory-filled synthetic oil for extended life

These specs can vary by manufacturer or custom order, so checking the nameplate and datasheet is essential.

Key Features of the Ghuk-Y44551/300

This gear motor is engineered for industrial resilience and performance. Here are the top features:

-

Heavy-Duty Housing: Cast iron body for superior strength and vibration resistance

-

Energy Efficiency: Meets IE2 or IE3 energy classes

-

Quiet Operation: Low-noise gearing for sound-sensitive environments

-

Thermal Overload Protection: Prevents overheating during long-duty cycles

-

Maintenance-Free Design: Long-lasting synthetic lubrication reduces service needs

Its seamless integration with automation systems makes it ideal for smart manufacturing applications.

Top Applications for Ghuk-Y44551/300

Due to its flexible torque and adaptable gear ratios, the Ghuk-Y44551/300 is used across multiple industries:

-

Food Processing Lines

-

Packaging Equipment

-

Material Handling Systems

-

Textile Machinery

-

Mining and Aggregate Equipment

-

Automotive Assembly Lines

Each of these use cases demands long-term reliability and consistent performance—traits the Ghuk-Y44551/300 delivers with ease.

Advantages of Using Ghuk-Y44551/300

There are several compelling reasons to choose this gear motor over others:

-

Long Service Life: Robust build and superior components extend operational life

-

Energy Savings: Reduced power consumption lowers electricity bills

-

Custom Configuration: Modifiable ratios and mounting styles

-

Ease of Installation: Standard dimensions simplify retrofits

-

Reduced Downtime: Fault-tolerant design minimizes production halts

Businesses looking for ROI on equipment investments often prefer this model.

How to Install the Ghuk-Y44551/300 Correctly

Proper installation ensures performance and longevity:

-

Prepare the Mounting Base: Ensure it’s flat, rigid, and aligned

-

Check for Proper Coupling: Avoid shaft misalignment

-

Secure Fastening: Use high-torque-rated bolts and check tightness

-

Electrical Hook-Up: Follow manufacturer guidelines for voltage and phasing

-

Lubrication Check: Confirm proper oil level if not factory-filled

Always follow the product manual or consult a certified technician.

Maintenance Tips for Long-Term Use

Like all industrial gear motors, periodic checks keep it running efficiently:

-

Inspect Oil Level: Every 6 months or as per operational hours

-

Monitor Noise and Vibration: Changes may indicate internal wear

-

Check Mounting Bolts: Re-torque annually

-

Electrical Inspection: Ensure terminal connections remain clean and tight

-

Cooling Vents: Keep clear from dust and debris

Proactive maintenance enhances the lifespan and reduces unexpected failures.

Common Issues and Troubleshooting for Ghuk-Y44551/300

While generally reliable, here are a few typical issues users face:

-

Excessive Heat: Often due to overload or insufficient ventilation

-

Unusual Noise: May indicate misalignment or bearing wear

-

Oil Leaks: Caused by worn seals or overfilled oil

-

Low Output Torque: Check for improper gear ratio or mechanical resistance

-

Intermittent Start: Electrical supply problems or worn brushes

Each of these issues has solutions, most of which can be resolved in-house or with technical support.

Comparing Ghuk-Y44551/300 to Similar Gear Motors

Compared to similar gear motors from brands like SEW Eurodrive, Nord, or Siemens:

| Feature | Ghuk-Y44551/300 | SEW Eurodrive R Series | Nord SK Series |

|---|---|---|---|

| Torque Output | Up to 800 Nm | Up to 650 Nm | Up to 720 Nm |

| Energy Efficiency | IE2/IE3 | IE2/IE3 | IE2 |

| Maintenance | Low | Moderate | Low |

| Noise Level | Low | Moderate | Low |

| Cost | Competitive | Premium | Mid-range |

The Ghuk-Y44551/300 offers an excellent balance of performance and affordability.

Ghuk-Y44551/300 in Smart Automation Systems

Today’s smart factories demand motors that can integrate with Industry 4.0 systems. The Ghuk-Y44551/300 supports:

-

Sensor Integration: For predictive maintenance

-

Variable Frequency Drives (VFDs): For speed control

-

IoT Monitoring: Via smart PLC interfaces

These capabilities future-proof your automation investment.

Where to Buy Ghuk-Y44551/300 Gear Motors

You can purchase the Ghuk-Y44551/300 from:

-

Authorized industrial automation dealers

-

OEM manufacturers

-

E-commerce sites like RS Components or Grainger

-

Direct from distributors for volume pricing

Always ensure you’re buying from a verified source to avoid counterfeit components.

Cost Analysis and Budget Planning

The price for Ghuk-Y44551/300 varies based on:

-

Power rating

-

Torque capacity

-

Customization

-

Brand

Expect a price range between $400 and $1500. Consider lifecycle costs, not just initial expense.

Certifications and Standards Compliance

This gear motor typically meets:

-

ISO 9001: Quality Management

-

CE Marking: European Compliance

-

RoHS: Restriction of Hazardous Substances

-

IEC Standards: Electrical Safety

These certifications reflect quality assurance and environmental responsibility.

Environmental Impact and Energy Ratings

With eco-efficiency becoming a key priority, Ghuk-Y44551/300 motors:

-

Consume less energy per unit of torque

-

Use long-life lubricants to reduce waste

-

Come with recyclable casing materials

This makes them suitable for organizations with green initiatives.

Real-World Testimonials and Case Studies

-

Automotive Plant in Germany: Reduced maintenance downtime by 42% with 60 units of Ghuk-Y44551/300

-

Food Packaging Line in Canada: Improved conveyor efficiency by 17% using VFD-compatible models

These stories underscore reliability across sectors.

Also read: 1-806-301-1929 BlackRock: Reliable Contact for Investment Support

FAQs

What is the typical lifespan of the Ghuk-Y44551/300 gear motor?

With proper use and regular maintenance, it can last 10–15 years in industrial environments.

Can the Ghuk-Y44551/300 operate in outdoor environments?

Yes, with an IP65 rating, it’s suitable for dust and water exposure, but extra enclosures are recommended in extreme weather.

Is the Ghuk-Y44551/300 compatible with VFDs?

Absolutely. Most models support VFDs for variable speed control.

Does the motor come pre-lubricated?

Yes, it’s usually factory-filled with synthetic oil, ready for installation.

Can I replace parts of the Ghuk-Y44551/300 myself?

Basic maintenance like seals or oil can be handled in-house. Gear or bearing replacement should be left to professionals.

Where can I find the datasheet for the Ghuk-Y44551/300?

Datasheets are typically available on the manufacturer’s website or through authorized distributors.

Conclusion

The Ghuk-Y44551/300 gear motor stands out as a rugged, efficient, and cost-effective solution for a wide range of industrial applications. From precise torque delivery to smart automation integration, it checks all the boxes for modern engineering demands. If reliability, performance, and affordability are on your checklist, the Ghuk-Y44551/300 deserves serious consideration.